Screen Printing

What is screen printing?

Screen printing is a process where ink is pushed through a screen that has been coated in a uv sensitive coating called emulsion, and burned to a specific design. Each different color of ink is printed through a different screen, requiring multiple screens to be used for multi-colored jobs. All of the screens required for a certain job are aligned (registered) on a press, and ink is pushed through each screen, leaving your design imprinted on a garment, poster, etc.

Ink Types

Our goal is to capture your vision. Choosing what ink types to use can completely change the look and feel of a garment. To help you along in the process, we offered some information on each ink type that we provide.

Standard Plastisol

Plastisol is our standard ink, but it still captures a high quality finish. We use the highest quality plastisol inks that we can get our hands on, and they work great on garments containing 50% or more cotton.

Softhand Plastisol

Our softhand plastisol is a special blend of our standard plastisol ink and soft hand additive. It gives the garment a softer and lighter feel.

Poly

Poly ink is used for garments containing more than 50% polyester. Poly prints turn out just as bright and vibrant as our plastisol prints, and are perfect for high performance sport shirts.

water based/discharge

Water based ink is extremely soft. While remaining bright and bold, water based ink has almost no feel, which is perfect for clients who want to achieve an extremely high quality finish and a more fashionable look.

Finishing Types

Relabeling

Relabeling is when we carefully remove the existing size tag from a garment and replace it with a custom printed neck label or woven label. Relabeling is a great way to take your branding to the next level.

folding & bagging

Folding and bagging not only helps to keep things organized and convenient for packing and shipping, but it adds an extra element to your product that shows attention to detail.

Embroidery

WHY USE EMBROIDERY?

Some garments are not suitable for screen printing, or maybe you just don't want the look of screen printing on your garments. That's where embroidery comes in. Embroidery is a process that uses needles and thread to stitch out a design. The result is a very high end, high quality product. This is very popular on garments such as caps, beanies, polos, etc.

Stitch Types

There are a vast variety of options when it comes to embroidery. The possibilities are endless, but to help you on your journey, we described some of the most popular stitch types below.

Standard stitching

The most basic, but still incredibly powerful. Create clean and bold impressions that are suitable for almost any application.

3D embroidery

3D embroidery uses foam to pop the design off of the garment. This technique is very eye catching and works best with more simple designs.

tackle twill Appliqué

Tackle twill appliqué is the process of stitching down twill fabric to cover large areas of a design. This works great for designs that take up more extensive areas of a garment.

woven labels/ patches

Used for high detail designs or just to add that extra special touch to a project. Woven labels are great for relabeling or hem tags, and patches are great for stitching on to garments, or just to simply distribute by themselves.

Digitizing

Digitizing is the process of turning your design into a file for stitching. Many embroidery shops outsource their digitizing to other companies because of how intense the process is. At ML Screen Printing, we are able to digitize in-house to ensure that every detail is dialed-in perfectly, as well as being able to stitch your design to multiple different garment types without the need for outsourcing the digitizing over and over again.

Vinyl Printing

We offer vinyl printing services for anything from large scale signage and vehicle wraps to banners and bumper stickers. Our vinyl prints include extremely high detail and a long lifespan while remaining eco friendly. Our vinyl prints are full color, and available in either gloss or matte laminate options.

Finishing Types

One reason vinyl printing is so popular is because it allows for a wide array of cut and finish options. We outlined a few processes below that we feel may help you when choosing how to go about your next vinyl project. If you don’t see what you’re looking for here, just ask! Chances are we’ve been there, done that, but if not, we would love to try something new.

Die-cut

Die-cut is where the vinyl and backer are both cut to the same shape. Die-cut can work for simple to fairly complex shapes.

kiss cut

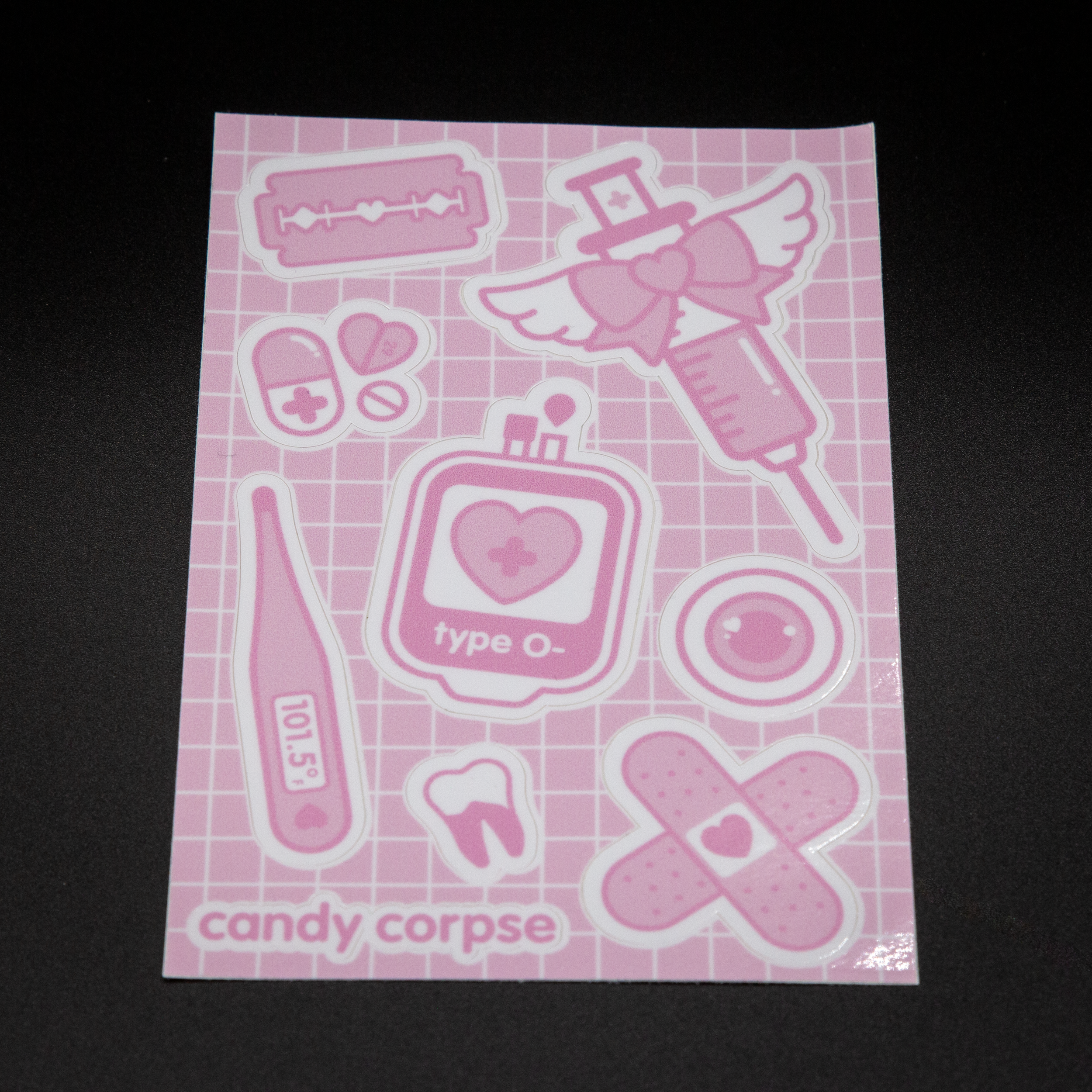

Kiss cut refers to two cuts: a contour cut (only through the vinyl), and a perf cut (through the vinyl and backer). Great for extremely detailed cuts where die-cut is not an option, or maybe you just like the look of a nice straight edge. This technique is also great for sticker sheets.

transfer decals

Used for designs that need a little help being applied like an extreme kiss cut. This technique is often done to create a graphic without a background.

Matte vs. Gloss

Both finishes are extremely durable. It all comes down to personal preference. Do you like your stickers glossy or flat?

Additional Digital Printing Services

Wall Flags

banners

Backdrops

Tents

Design

ML Screen Printing has a professionally trained art department to help bring your ideas to life in a creative and effective way. Whether you need a t-shirt design for your family cookout, or complete corporate branding, we have your back.

Design Samples

Below are some of our favorite designs that we had the privilege to create.